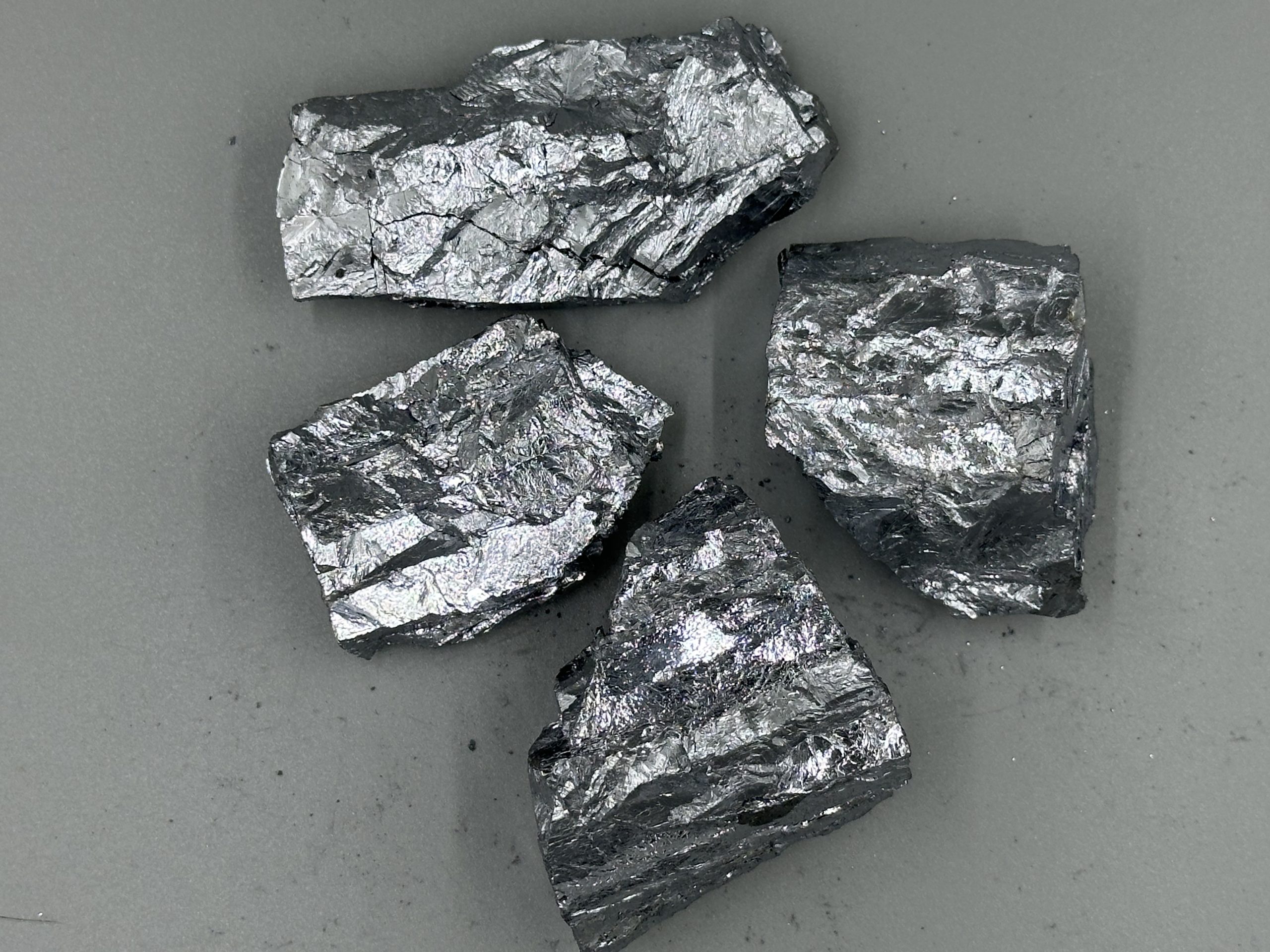

Chromium

Chromium – Recycling and Scrub Overview

Aluminium is one of the most efficiently and widely recycled metals in the world. Lightweight, corrosion-resistant, and highly durable, aluminium is used in transportation, construction, packaging, electrical systems, and consumer goods. Its recyclability and low environmental impact make it essential to sustainable industrial practices.

Industrial Applications

Stainless Steel Manufacturing

Chromium is the key element that gives stainless steel its corrosion-resistant properties. Stainless grades such as 304, 316, 430, 2205, and 17-4 PH typically contain 10.5% to 26% chromium, depending on the application.

Tool & Alloy Steel Production

In high-speed steels and die steels, chromium enhances hardness, wear resistance, and toughness under extreme working conditions.

Surface Hardening

Chromium is used in chromizing, thermal spray coatings, and hardfacing to improve surface durability, especially in components exposed to abrasion, high heat, or aggressive chemicals.

Foundries & Steel Mills

Chromium-bearing scrap is a vital charge material in electric arc furnaces (EAF) and induction furnaces to achieve desired alloy specs in melting operations.

SSM’s Role in Chromium Supply

At Shams Al Sajaa Metal Scrap Tr. (SSM), we offer high-quality chromium-rich scrap and alloy inputs for:

- Stainless steel producers

- Tool steel manufacturers

- Specialty alloy foundries

- Re-alloying and master alloy blending

Our chromium sources include:

- High-chromium stainless scrap (e.g., 430, 446, 17-4)

- Tool steel scrap (e.g., H13, D2, T1)

- Ferrochrome-based residues and returns

Using advanced sorting, XRF/OES verification, and clean processing methods, we ensure material consistency and traceability. Our chromium feedstock helps clients reduce raw material costs, maintain alloy accuracy, and support sustainable metallurgy.

Sustainability Focus

Chromium recycling plays a major role in reducing the environmental impact of steel production. By reintroducing chromium-rich scrap into the melt cycle, SSM supports:

- Lower CO₂ emissions

- Reduced dependence on mined ferrochrome

- A circular metal economy

Looking for Chromium Feedstock?

Whether you're a stainless steel mill, a tool steel manufacturer, or an alloy foundry, SSM provides trusted chromium solutions tailored to your melting and specification needs. Contact us today to discuss grades, availability, and custom blending options.